DAL-A Certifiable Auto Pilot and Mission Computer LRU for Airborne Applications

The Defense industry is witnessing an unprecedented growth in the use of Airborne Platforms for combat and ISTAR missions. This has resulted in an increasing demand for efficient SWaP optimized DO-178C Safety Certifiable airborne systems using LRUs that assure hassle-free future system upgrades. Auto Pilot and Mission Computers are critical components of both manned and unmanned airborne platforms. These systems allow Airborne platforms to perform entire missions autonomously, or with minimal involvement of an operator.

Auto Pilot systems receive data from an array of sensors including Gyros, Magnetometers, Accelerometers, Radars, Navigation Systems, Engines and other peripherals. The received data is processed to capture, record and send out critical flight information on altitude, velocity, position and direction of the platform to the flight control actuators and other systems to assist autonomous operations. This case study outlines Mistral’s expertise in design and development of a DAL-A Certifiable Auto Pilot LRU which is critical to carry out flight operations including Take-offs, flight manoeuvres, and landing in addition to various user defined autonomous missions; and a DAL-C Certifiable Mission Computer (LRU) that helps receive, process and store ultra-high-definition images captured by the Airborne Platform.

The Customer

A leading Aerospace and Defense solutions company.

The Requirement

The customer approached Mistral to build an advanced LRU-based Auto Pilot and Mission Computer system for their ongoing Project. The customer was keen on a small form-factor, SWaP optimized LRU to ensure maximum flight efficiency and hassle-free upgradation in future. The Auto Pilot and Mission Computer LRU had to be a DO-178C and DO-254 Level A Safety Certifiable system.

The Solution

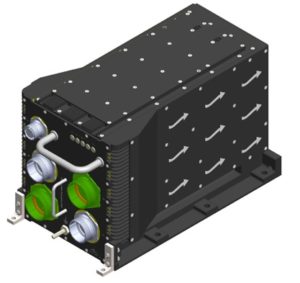

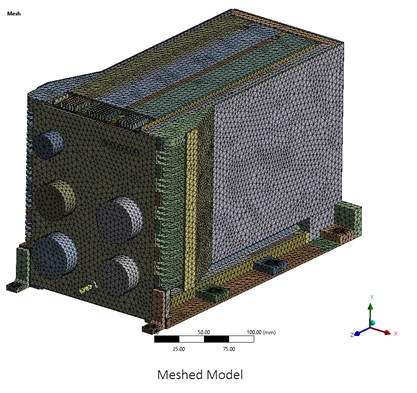

Mistral and the customer jointly conducted a thorough requirement analysis and agreed on the system specifications including COTS modules, software and dimensions for Auto Pilot and Mission Computer. Considering the key requirements of a SWaP optimized LRU that meets DAL-A safety parameters, Mistral designed a rugged 3U ¾ ATR Chassis with a VPX backplane, which can house multiple COTS SBC Modules, I/O Cards, GPU Cards, Switch, SATA Storage cards, load sharing Power Supply and mating I/O Connectors.

The LRU was designed based on Integrated Modular Avionics (IMA) Architecture using VxWorks 653, as the system handles multiple avionics functions of different criticalities. The use of VxWorks 653 enabled multiple applications running concurrently on multiple partitions in the system.

Hardware

The Hardware of Auto Pilot and Mission Computer LRU was realized using COTS modules from Curtiss-Wright and custom designed SATA Cards, I/O Panel, Power Supplies and multi-slot backplanes.

Auto Pilot and Mission Computer LRU:

The Auto Pilot and Mission Computer LRU was built into a ¾ ATR Chassis designed by Mistral, with a dual redundant system to ensure operational continuity of the platform in the event of a system failure. The system includes DO-254 DAL Certifiable I/O cards, SBCs, custom designed SATA Card and dual redundant Power Supplies. The I/O Panel, custom designed with MIL-38999 standard circular connectors, brings out the I/O lines from the LRU.

The heart of the LRU is a 3U VPX Conduction Cooled T2080 Processor Card. It includes,

- 3U VPX Conduction Cooled I/O Card with MIL1553, A429, RS-232, RS-422/485 Serial I/O, Analog Interfaces

- DO-254 and DO-178C Safety Certifiable 3U VPX AMD E8860 Graphics and Video Capture Module

- 3U VPX Conduction Cooled 20 Port Ethernet Switch

- Custom-built 1TB SSD SATA Card

- Custom-built I/O Panel with MIL-38999 Circular Connectors

- Custom-built ¾ ATR Conduction Cooled Chassis with 6-slot 3U VPX backplane

- Custom-built Dual Redundant Power Supplies

- DAL-A Certifiable VxWorks 653 RTOS on SBC, BSP and Drivers

3U VPX Backplane Design:

The backplane was designed to meet the dual redundancy requirement of the system. The main highlight of the backplane design is the conversion of RS-232 from IO Card to RS-485 and RS-422 and the bi-directional communication circuitry between the Auto Pilot LRU and the flight actuators, over these interfaces.

SATA Storage Design:

Mistral designed and integrated solid-state SATA Storage cards for Auto Pilot and Mission Computer LRU. The storage units provide 1TB of storage with SATA Gen3 interface (6.0Gb/s). The unit stores logs from various peripherals and engine of the Airborne Platform.

Power Supply Design:

A dual redundant power supply is designed and built into Auto Pilot and Mission Computer LRU. The load sharing Power Supplies cater 250W power with input supply voltage of 18 V to 36 V. The Power Supplies are built with fully protected output in addition to input overload and reverse current protection. Mistral has also implemented a health monitoring mechanism that helps to continuously check and monitor the health status of the power supply over the serial port.

Software

The Auto Pilot and Mission Computer LRU runs VxWorks 653 RTOS, an Integrated Modular Avionics (IMA) DAL-A certifiable platform. Mistral integrated BSPs and Drivers which are certifiable to DAL-A levels on the LRU. This was in line with the hardware modules used. In addition to fully integrated units, Mistral also provided the Wind River VxWorks 653 Development Environment on customer provided computers.

The BSPs and Drivers integrated by Mistral includes,

- DAL-A Certifiable VxWorks 653 BSP for T2080 based SBC

- DAL-A Certifiable VxWorks 653 v3.x Device Drivers for 3U VPX Graphics and Video Capture Card

- DAL-A Certifiable VxWorks 653 v3.x Device Drivers for I/O Card

Application Framework for IO Card:

Mistral designed and developed an application framework using VxWorks 653 v3.x to test all the functionalities of the IO card.

Mechanical Design

The LRU is integrated into a custom designed ¾ ATR Forced Conduction Cooled Chassis with 3U VPX backplane that can house up to Six Cards and two Power Supplies. The Chassis is built with aero grade Aluminum 6082 alloy using milled block construction and complies with ARINC 404A – Air Transport Equipment Cases and Racking Standard. The Chassis also meets the stringent requirements of DO-160G, MIL-810, MIL-461E standards for environmental and EMI compliances.

The LRU is integrated into a custom designed ¾ ATR Forced Conduction Cooled Chassis with 3U VPX backplane that can house up to Six Cards and two Power Supplies. The Chassis is built with aero grade Aluminum 6082 alloy using milled block construction and complies with ARINC 404A – Air Transport Equipment Cases and Racking Standard. The Chassis also meets the stringent requirements of DO-160G, MIL-810, MIL-461E standards for environmental and EMI compliances.

Mistral optimized the design of Chassis Fins to obtain maximum thermal efficiency and avoid over heating conditions that can significantly affect the performance and durability of electronic devices. The custom-built IO Panel integrated into the Chassis is provided with MIL-C-38999 type Connectors for power and I/O Signals.

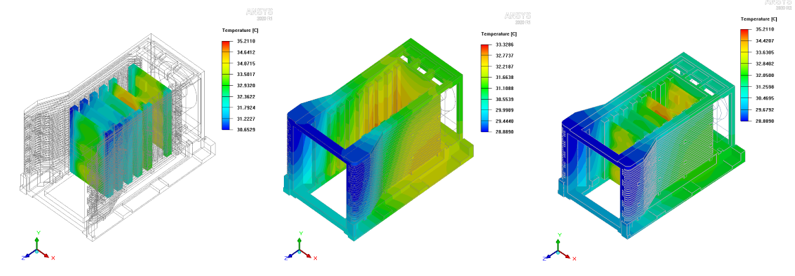

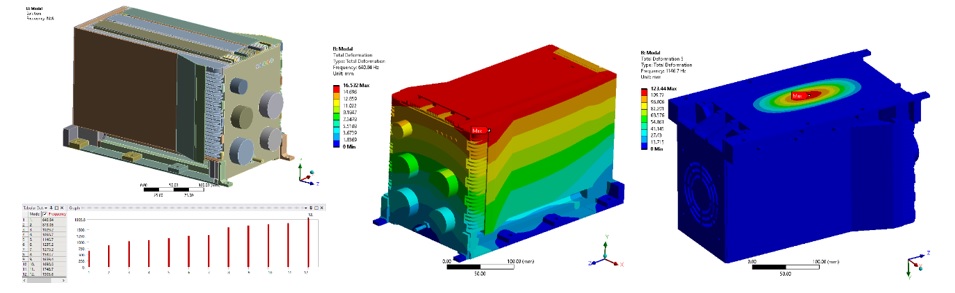

Thermal and Structural Analysis:

Mistral performed Thermal and Structural Analysis of the 3D Model to ensure that the system meets demanding needs of high temperature, vibration, shock and altitude among others in harsh operational environment. Thermal analysis was done with respect to forced air convection mode with steady simulation for an ambient Temperature of 25°C and 65°C. The Chassis were designed in such a way that power dissipation is spread equally over the card at primary side of the backplane without heat sink.

Mistral conducted Modal Analysis, Random Analysis, Transient Structural (Shock) and Static Structural Analysis and Deformation and stress for the LRUs to validate structural compliance.

Electrical CAD:

Mistral also conducted Signal Integrity and Power Integrity analysis of the design at various levels to ensure compliance with electrical specifications as per standards.

Mistral also calculated and provided MTBF (Mean-time Between Failures) and FMEA (Failure Mode Effect Analysis) reports to the customer as per MIL-STD-1629 for each component in the system.

DO-254 and DO-178C Safety Compliance

Mistral assured that DO-254 Compliance evidence can be made available for all the hardware components during the process of certification. The entire system software supplied by Mistral qualifies to DO-178C Level-A Safety Level. Mistral also ensured the availability of artifacts for individual BSPs, Drivers and RTOS for DO178B compliance from respective OEM’s, to meet certification requirements.

Mistral provided Hardware and Software manuals, various reports including Thermal and Structural Analysis, Software Programming Manuals, Backplane Interconnect Details, IO Connector ICD etc. along with the System.

Environmental Standards

Mistral provided support to the customer for the Environmental Qualification activities of the System. The chassis and cards of both Auto Pilot and Mission Computer were designed to adhere to following Environmental Standards.

- MIL-810

- DO-160G

- MIL-461E

Read the full case study to know more about design challenges and how these challenges were addressed.