Industrial PLC Gateway for Fluid Mixing System

Power Line Communication enables combining data and power over one line saving new data channel establishment cost. Over the last decade or two, PLC systems have gained much interest in the field of industrial and smart grid, enabling a range of applications such as home automation, automatic meter reading and factory Automation, among others.

This case study showcases Mistral’s expertise in designing and developing a PLC gateway for a complex fluid mixing system, from concept to deployment, covering the entire product development cycle including high level design & analysis, schematics design, PCB layout design & fabrication, component procurement & component assembly, Linux system software development, driver development, BSP porting, hardware board bring up & interface validation, hardware-software integration testing, Web User Interface design and development of various software utilities.

The Customer

A leading solution provider of fluid / hydraulic controllers and pumps.

The Requirement

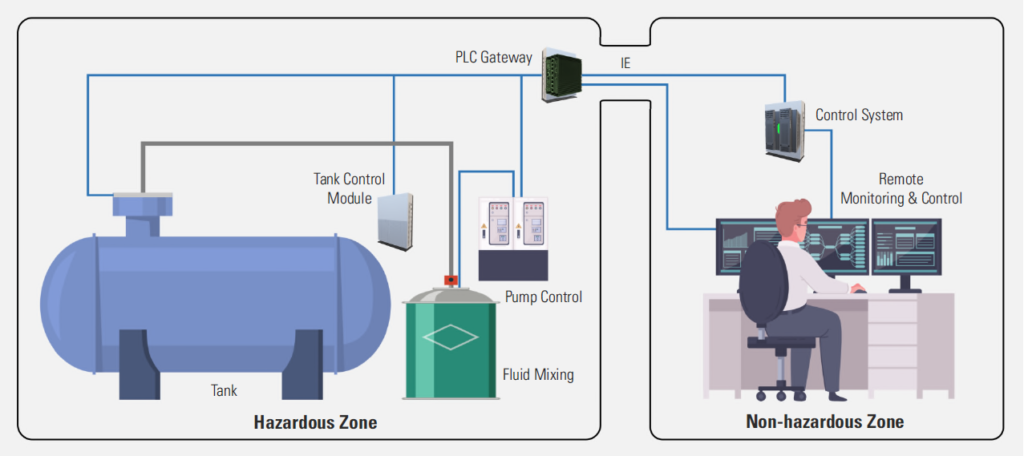

The customer is developing an advanced version of their fluid control systems, including pumps, mixers, proportioners, valves etc,. They want to reduce the installation cost, minimise cable clutter between the various systems (control, HMI and other components) while increase safety of users. The customer approached Mistral to build an advanced Power Line Communication (PLC) gateway, a key communication and control module in the system, combining the power and data into single set of cables. Installations, involving highly inflammable solutions, demand the HMI and any user interaction to be physically separated from the storage or fluid dispensing systems. Such installations would have to be separated into functional zones – Hazardous and non-hazardous zones.

As part of safety measure, any component being placed in hazardous zone needs to

be intrinsically safe. The communication between the components connecting two different zones has to be intrinsically safe too. These cable installations, their repair and maintenance will be expensive for the users.

The customer requirement is to eliminate these communication cables and route all the communication signals through the Power Line that is fed into the Hazardous zone. The PLC Gateway would be installed at the boundary of hazardous zone, which can be connected to HMI panels or other control systems over a standard industrial field bus, and transmit the communication signals to various components in the hazardous zone.

Fluid Control System

The customer also wanted a Web-based User Interface that allows easy and quick configuration of various components of the system and enables users to access system data, monitor, control and manage the performance parameters remotely. In addition, the PLC Gateway must be configurable as a stand-alone control system with its own interface over the Web-server.

The Solution

Mistral carried out a detailed requirements analysis, identified the key hardware and software specifications and came up with a feasible design for the PLC Gateway. The Gateway plays a dual role in the Fluid Control System. It acts as a PLC gateway and also as a controller over a high-speed serial bus that interfaces with various I/O modules.

Mistral came up with a two-board architecture to isolate the digital and analog sections – a Digital Board consisting of all Communication Interfaces, Digital Input / Output Interfaces, Signal Converters, and various LED indicators and a Power Board with a Base Band Processor that integrates three-phase AC-DC circuits and PLC coupling circuits.

Mistral also developed the System Software and drivers for various interfaces and communication protocols, and a Web-based User Interface that allows setup and configuration of the gateway remotely. The system is designed to work as a slave, when configured with external logic controllers over FieldBus IE, Ethernet IP, CANOpen, MODBUS-TCP, and MODBUS RTU among others.

Hardware

The PLC Digital Board is built around

- Dual Cortex A7 with

- 1GB DDR3, 4GB eMMC Flash memory

- USB Type-A and Type-C

- Multiple Industrial Ethernet ports.

- Multiple Analog and Digital I/Os , Temperature sensors, Voltage and Current Monitoring IC,

- Watchdog Controller and TPM (Trusted Platform Module)

- CANOpen, DeviceNet field bus protocols over CAN and Modbus protocol using RS485 Transceiver

- The Power Board consists of PLC Baseband Processor interfaced to the Cortex A7 over

- RGMII (Ethernet) interface and PLC coupling circuits.

System Software

The Fluid Control System consists of different components – Pumps, Tanks and Agitators. Each of these components operates independently and includes a set of configuration / run-time parameters. The Linux based PLC Gateway system software designed by Mistral includes a software module for each of the above components. These software modules enable control and configuration of each component, gather run-time data for further processing (logging, monitoring etc.) and provide mechanism for software/firmware updates of the system.

Mistral modified the Linux Kernel to realise the features as required by the customer. Various communication interfaces such as CAN, I2C, USB, WiFi/BT, Ethernet, RS385 were enabled. Linux driver for GMAC driver has been modified to support PHY Mode. Mistral developed Linux driver for realizing Ethernet interface over USB interface. Other Linux modifications include Drivers for DAC, DTS (Device Tree Source Files) for Digital Input/Output, DTS for LEDs, etc.

The software development included

- Linux BSP & Driver development

- Linux BSP porting

- Board bring-up

- Driver integration and testing for various peripheral

- Hardware and BSP software Integration testing

- PLC Base Band Software integration

- Establishing PHY Mode communication

Embedded Applications

Mistral designed and developed an embedded application running on the processor to realize the following use cases:

- Daemons for system monitoring

- System Logging

- Parametric data logging in Timescale DB

User Interface and Web Server

The PLC Gateway provides a centralised terminal to control and configure the Fluid Control System. Mistral designed and integrated an intuitive and user-friendly Web-based User Interface that enables configuration of the system remotely. The User Interface provides access to each component of the system to ensure easy monitoring and management.

The Web Server is designed to interface with the system and read/write Shared Memory (SHM) to drive various component related parameters, configuration and run data. The Web Server was implemented with user management and support for various roles that include Operator, Maintenance, Supervisor, System Admin and Developer.

- Enables complete control and monitoring of the Fluid Control System from the non-hazardous zone

- Provides access to Hardware, System Settings, System Configuration, System Logs, various interfaces and User Management Settings

- Provides access to PLC Network Management Utilities including upgrading/updating the Baseband Firmware, Configuration of the PLC network, Configuration of local and remote network nodes, etc.,

- Access to the operator console without login

- Provisions for configuration of connectivity interfaces like Industrial Ethernet Field-Bus, CAN Field-bus, RS-485, RS-422, and Power Line Communication

- System Configuration Web UI is provided with a feature to map the functionality to the Input / Output GPIOs.

CODESYS Implementation

Mistral has implemented CODESYS run-time in the Digital Board along with necessary IO drivers/libraries for effectively using the CODESYS environment. The board executes the tight control loop performing read/write operations of the IO modules connected over high-speed serial bus.

Protocol Implementation

Various Industrial Protocols such as ProfiNET, EtherNET/IP, CCLink, MODBUS TCP, CANOpen slave/device functionality were integrated on the PLC Gateway.