An Insight into Product Engineering Services

WHAT IS PRODUCT ENGINEERING SERVICES?

Product Engineering Services refers to the use of Embedded software, hardware design & Industrial Design techniques to develop an electronic product. Services or consulting companies offer Product Engineering Services across a wide spectrum of domains -Consumer Electronics, Industrial Products, Wearable Electronics, Medical Devices, Assistive Devices, Automotive Electronics, Aerospace and Defence, and more. Product Engineering Services involve a wide range of programming tools, processors / microprocessors, memory devices, interfaces, operating systems, UI Tools to design and engineer a product. Apart from this, it considers various quality and environmental regulations to ensure safe and secure deployment of products.

Product engineering services in the current scenario aims to achieve:

- A product with greater adaptability and scalability

- New and Better features with enhanced user experience (UX)

- Optimized product cost

- Quick to market

A Product Engineering process manages the entire life cycle of a product from the inception of an idea, feasibility study, design to deployment of the product. This is a process that involves various stakeholders including product managers, technical architects, business analysts, etc. Over time, product development companies have realized the importance of developing products that are more user-centric and fulfill a latent need for the product in the society.

PROCESS OF PRODUCT ENGINEERING

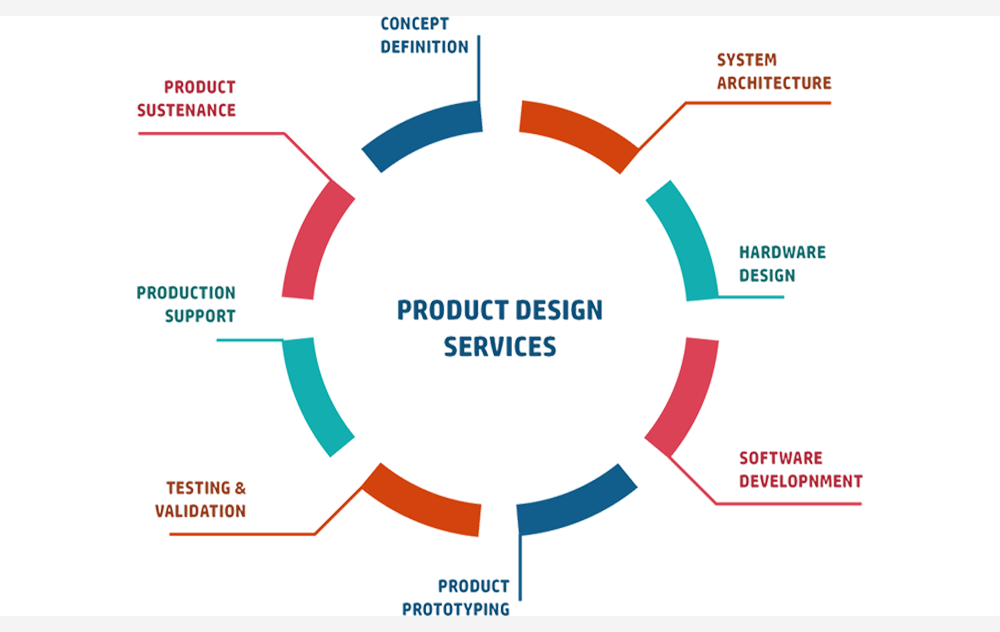

A typical product engineering services activity includes Hardware Design, PCB Layout and Analysis, Software and Application Development, Testing and Validation, Product Prototyping, Production and Product Lifecycle management. Let’s look at this process step by step.

- Conception of the idea: An idea is conceived and detailed in terms of its application, usage and features and how it is going to impact/enable the world. Based on the feasibility of the idea, it is pursued, modified or discarded.

- Design: Now that you have a concept it needs to be converted into a product design. Product developers looks at the Hardware, Software & Industrial design specifications necessary to realize the product. This includes identifying the right OS, the processor, the memory, system partitioning between hardware and software, interfaces needed to realize the product, UI/UX and industrial design.

- Development: In the development phase, the product is brought to physical existence based on the design. This include the PCB Design, mechanical CAD, system software development, Middleware development and integration, application development etc. Any modification or deletion to the design decisions made earlier is executed at this stage. The product also undergoes various Testing and Validation at module and system to ensure performance and quality of the product designed is as per expectation.

- Prototyping: A prototype is a ready product or an early sample that resembles the final product. Prototypes enable testing and validation of various features envisioned earlier during the design stage. Prototypes will be deployed in controlled environment to monitor and analyse its performance and verify its compliance with applicable environmental and quality standards.

- Production and Delivery: On approval and acceptance of a prototype, the product will be labelled ready for production. The Product Engineering lifecycle include production support as well. A close communication is maintained throughout the processes between the product engineering as well as production teams to ensure seamless release of final product.

- Product Lifecycle Management (PLM): PLM forms the key aspect of any product-based Business. It is critical to remain competitive by continuous enhancement to the product and maintaining customer satisfaction. PLM helps in timely release of relevant software updates, patches to ensure periodic upgrade, feature enhancement and customer support at all levels. PLM also involves obsolescence management to ensure that all the relevant components are available or appropriate replacement is identified, tried and tested for the duration the product remains in production.

OUTSOURCING OF PRODUCT ENGINEERING SERVICES

The demand for product engineering services has grown as businesses are compelled to keep up with the evolving and dynamic environment. As the size of the technology market increases, companies compete to deliver the best products with enhance user experience. Product companies are increasingly focusing on their core strength, i.e. conceptualizing and marketing their product and leverage on the skillsets of product engineering services companies to help release their product in a timely and advantageous manner.